XCMG recently launched cranes for the North American market.

XCA150_U All-terrain Crane

With the 6-section boom of 203.4 ft and a single-cylinder pinning telescoping system, XCA150_U has a maximum lifting capacity of 150 USt, the maximum lifting height of 303.5 ft., and maximum working radius of 236.2 ft. The modified counterweight meets different slewing radius.

Human-machine interaction system, intelligent crane boom technology and intelligent traveling control system offer the most intelligent operation planning and operation safety protection. Convenient wireless remote control can realize operations of outrigger extending/retracting, lifting, luffing, slewing, counterweight assembly/disassembly and jib folding/unfolding, which enables the operation by only one person.

The new cab has larger internal space, and the driving operation will be more comfortable. The access system has been optimized, making climbing safer. The cameras equipped at boom head, winch and counterweight, as well as the backup camera, have better visibility for driving operation.

XCA150_U can be matched with a variety of dollies (three axles, four axles, five axles), and the axle load can meet the requirements of all regional licensing in North America. With the 525/80R25 tires equipped as standard, the high-speed turning maneuverability is improved by 15%, the off-road ability is improved by more than 20%, and the emergency braking distance is shortened by 15%.

XCR100_U Rough Terrain Crane

With strongest lifting performance of the same tonnage product in the industry, XCR100_U has a slewing angle self-adjusting and multi-mode steering technology to meet the construction requirements in narrow sites. With energy-saving hydraulic system, hydraulic torque converter system and ECO energy-saving control, the crane operation is energy-saving and environmental friendly. Multiple technologies such as load planning, fault self diagnosis and driving safety detection are adopted to make the vehicle intelligent and safe.

The crane has a boom length of 157.4 ft with wide working range. Its lifting performance is 3%-19% ahead of competitors. Three telescoping modes provide higher operation efficiency and better adaptability for different operation modes.

With energy-saving hydraulic system, hydraulic torque converter system with a lock and ECO energy-saving control, the comprehensive fuel consumption is reduced by 15-24%, and the high-speed driving fuel consumption is reduced by 20%.With large displacement dual variable piston pump and automatic dual pump control, the working efficiency is increased by 13%, and the inching control and smoothness are increased by 20%.

Slewing angle self-adjusting and multi-mode steering technology with one-key selection make the minimum turning radius only 21.3 ft., the smallest in the industry, flexible and convenient for jobsites transfer.

XCMG HMI system integrates functions such as loading planning and fault self-diagnosis with abundant information, user-friendly screen and easy operation.

Automatic braking, audio and visual alarm for overloading, automatic speed limitation, driving safety active protection and faults classified management can greatly improve the crane safety.

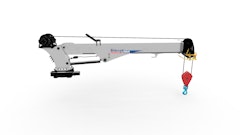

XCT60_U Boom Truck Crane

XCT60_U is a large tonnage boom truck for the North American market, mainly mounted on the American Kenworth chassis.

XCT60_U enjoys performance in its class with strong adaptability to operation modes. The length of the 5-section boom is 47 m(154 ft), 1m-7m higher than that of the local competitors in North America, and the lifting performance is 3%-5% ahead.

Superstructure can be mounted on the local mainstream Kenworth 5-axle chassis. It is adaptable to the chassis with single steering axle+floating axle+three-axle drive in the U.S., and the chassis with dual steering axles+three-axledrive in Canada. The requirements in different regions can be met. At the same time, it can realize jobsite transfer with full counterweight, meeting the requirements of road permits in key states and regions with reduced costs. It makes driving across states more convenient.

Optimized ergonomic design provides excellent driving and operating experience. The new cab with increased internal space, making driving more comfortable. The optimized layout of instruments and switches is easy to operate. More friendly HMI system with touch display conforms to the actual needs of users.

The product is designed for the North American market,with improved functions such as centralized lubrication, small remote controller, hydraulic proportional slewing brake pedal, as well as optional equipment, such as basket, wireless remote control, boom head camera etc. Which provides users with functions that meet local operating habits and needs.