Grabbing a picture with the Caterpillar team at the pre-show dinner

Grabbing a picture with the Caterpillar team at the pre-show dinner

Our team’s booth visits and the equipment and technology at the show cover these trends and many more. Among them are:

- A move to electric power, particularly for equipment used indoors or other areas where exhaust might be a safety risk

- Swappable batteries to extend equipment usage

- Cordless tools (specifically featured by Milwaukee Tool)

- Using technology to improve and simplify tasks for operators

- A desire to provide an entry point for small concrete contractors

Our team’s booth visits and the equipment and technology at the show cover these trends and many more.

We were happy to talk with Kevin Coleman about the new CTLs.Johanna Kelly

We were happy to talk with Kevin Coleman about the new CTLs.Johanna Kelly

We also interviewed Jonathan Randall, president, Mack Trucks North America, to get his insights into the importance of World of Concrete, his perspective on the industry moving into 2024 and the challenges that construction faces. Randall feels that we still have lessons to learn from the pandemic and that the industry is still rebounding from the supply change issues caused by it. His full podcast will be available soon.

We also talked with Dennis Howard, writer of “Dennis in the Dirt,” about his impressions of the show and the industry. His full video interview is now live.

Liebherr

Liebherr’s Divisional Director of Concrete Technology Guilherme Zurita begins the press conference discussing the newest concrete pump, the 38Z4 XXT.Lori Ditoro

Liebherr’s Divisional Director of Concrete Technology Guilherme Zurita begins the press conference discussing the newest concrete pump, the 38Z4 XXT.Lori Ditoro

Liebherr’s Divisional Director of Concrete Technology Guilherme Zurita, said, “We are excited to exhibit at World of Concrete 2024, showcasing our newest concrete pump, the 38Z4 XXT. This premier industry event is the perfect opportunity to officially debut our most advanced 4-section pump that delivers enhanced performance, leveraged by the already proven Powerbloc and best-in-class operational support solutions, such as the XXA stability support system.”

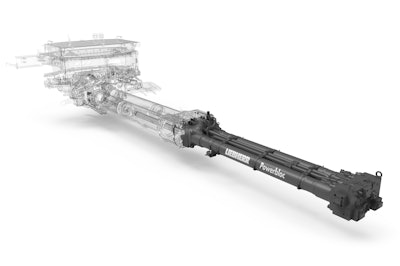

The 38 Z4 XXT truck-mounted pump with a Powerbloc pumping kit also has a stability assistance system. The pump increases productivity and improves safety by helping the operator use the boom without guessing. It also has an exclusive outrigging system that shows its strengths particularly when it comes to narrow supports, so confined spaces are no problem. It also has a four-part distribution The 38 Z4 XXT truck-mounted pumpLiebherr USA, Co.

The 38 Z4 XXT truck-mounted pumpLiebherr USA, Co.

Next discussed was the THP 80-LP, which was released during World of Concrete 2022. The newest addition to the Liebherr product portfolio, it was specifically designed for the North American market based on feedback from industry experts. The THP 80-LP is the most compact unit in Liebherr’s range of truck-mounted pumps, with a compact but powerful pump design. It is mounted on a two-axle, boomless truck chassis and weighs around 22,684 pounds, significantly lighter than truck-mounted boom pumps. This is convenient for customers because it does not require a commercial driver’s license to operate. The truck also includes two water tanks and ample storage for tools and other components. It has an International Trucks body and a transmission from Allison Transmission. THS 110 D-K crawler concrete pumpLiebherr USA, Co.

THS 110 D-K crawler concrete pumpLiebherr USA, Co.

Also new at the show was a wheel loader series (L 526, L 538 and L 546). Liebherr redeveloped and fundamentally revised its range of mid-sized wheel loaders. The L 546 for power earthmoving was on exhibit. The arm has maximum breakout, holding and lowering forces. The new L 526, for example, has around 20% more engine power and more than 20% higher breakout forces than its predecessor. The L 538 and L 546 models also have performance increases in all areas. For example, the optimized travel drive’s increased traction ensures that the new wheel loaders accelerate dynamically in  The Powerbloc pumping kit that also has a stability assistance systemLiebherr USA, Co.

The Powerbloc pumping kit that also has a stability assistance systemLiebherr USA, Co.

Finally, the team covered the 2.25 M ring pump mixer, which focuses on the precast industry. The paddles and mixing arm are designed to improve mixing quality. The mixer cover, free from overhead attachments, makes opening the mixer possible. Depending on the application, it can be opened between 30% and 60%. This ensures easy access from above and simplified maintenance. The gear and drive motors are below the mixer and are easily accessible. This allows sufficient room for the components required for material feed and dedusting on the upper side.

Toro

Next up was an informative tour of the Toro booth. Marketing Manager Kaitlyn Ingli first shared the ultra buggies, which were released in 2012 and new tracks were added in 2016. These new tracks are better on turf. In 2021, Toro added a swivel tube for better visibility and versatility, which is particularly ideal for landscapers.

New at the show was the electric Ultra buggy. It has a 2,500-pound capacity and is ideal for indoor use. The electric Ultra buggy travels through a door frame without any adjustments and allows for indoor loading instead of hauling loads outside. The electric version is now available for shipping.

The team was also exhibiting the next-generation eDingo 500 compact utility loader during World of Concrete. This machine, which also fits through doorways, is ideal for floor scraping in the concrete industry. The new design has a hinge pin height of 81 inches, which allows for clearing into most standard dumpsters and a 6.5-gallon-per-minute hydraulic flow.

It currently has four 30-inch attachments available (announced in October 2023), and these attachments also fit through doors when connected to the compact utility loader. They include:

- Standard bucket

- Adjustable forks

- Floor scraper

- Grapple bucket

So fun to meet Kelsey Batschelet and Kaitlyn Ingli and learn about the e-Dingo 200 wheeled buggy.Toro Team Member

So fun to meet Kelsey Batschelet and Kaitlyn Ingli and learn about the e-Dingo 200 wheeled buggy.Toro Team Member

This machine is ideal if one room needs to be worked or if operators are working in an active building. It also offers indoor and outdoor tire options. However, the outdoor tires cannot fit inside. The eDingo 500 replaces manual jobs with a machine in these tight spaces and improved worker safety.

Also on exhibit, the eDingo gas and diesel tracked, TX 700, which was released in 2023, has an in-between power capacity. It also has a delicate T-handle control that is intuitive for operators. It has a 750-pound operating capacity and can use the wide and narrow attachments.

KUBOTA

Next up for our team was the KUBOTA press conference where the team celebrated 50 years in concrete. In addition to this milestone, KUBOTA launched several new machines.

First was the KX 080-5 Excavator, with an auto-shutoff feature and larger cab and floor space. A rearview camera is standard along with other standard features to help the operator. This goes along with another theme of the show: technology to make the operator’s job simpler.

The KUBOTA team prepares for the press conference.Lori Ditoro

The KUBOTA team prepares for the press conference.Lori Ditoro

The KX 080-5 can be equipped with rubber or steel tracks and has a 19,000-pound operating weight with an optional 400-pound counterweight. The hydraulic hoses and lines are tucked in for safety.

The team also shared two new RTVS—the X 1130 and the RTV X. With 6-foot bed, the X 1130 has a diesel engine and 400 pounds of capacity. A special feature on it and the RTV X is a ProKonvert bed that can open from either side. Also, all sides can be let down for a flatbed or they can be removed for added flexibility. It is available now and began being shipped in November 2023.

Ignite Attachments

Interesting to learn about the tools for concrete contractors from Ignite AttachmentsIgnite Team Member

Interesting to learn about the tools for concrete contractors from Ignite AttachmentsIgnite Team Member

For protection and safety, all cables and wires have nylon sheathing (which is included in all Ignite Attachment attachments). The breaker’s flat-faced couplers connect under pressure and are easy to get on and off.

Made in U.S., this attachment has two tools instead of one:

- The moil point breaks the concrete.

- The chisel provides more control, breaking the concrete in a line, which makes life easier for the operator.

A nitrogen charge kit (shipped pre-charged) and a tool kit are standard.

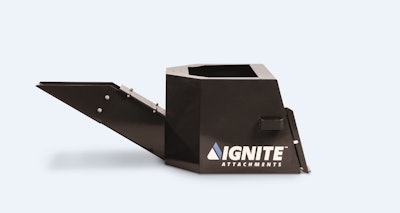

The team also announced a concrete chute bucket that can be used with a skid steer or CTL. For smaller jobs, it holds ¾ yard of concrete, and teams don't need a pump truck. This allows concrete contractors to work on their schedule.

Ignite's concrete chute bucketIgnite Attachments

Ignite's concrete chute bucketIgnite Attachments

Ignite Attachments also exhibited a 72-inch sweeper bucket for jobsite cleanup. Used on the front of skid steer, the sweeper bucket has an optional gutter brush or curb sweeper.

The company also shared a new business expansion in 2024 including fluids, lubricants and ground-engaging wear parts. New lines, including hydraulic fluids, grease, cutting edges and teeth. These additions will be available through the company’s website and its reseller network. The goal is to deliver quality and dependability with the convenience of an online shopping experience. According to the team, they have been working on this expansion for about a year or more.

Bobcat

It's always fun to try out the equipment.Erika Schrader

It's always fun to try out the equipment.Erika Schrader

This machine provides the same operating experience as diesel with no emissions or noise. The battery can charge using a 120-volt or a 240-volt connection. The runtime with aggressive operation is about 2 hours with 4 hours to 8 hours for lighter operation. The retractable undercarriage allows the E10e to enter tight spaces.

Next up was the E-40 Excavator, which was designed to fill a gap in the market. A 4-ton machine, it fills a need for compact trailering and maneuverability to complete challenging work on confined jobsites. It also uses the same attachments as other models.

Bobcat Power was rebranded from Doosan Power, but the equipment is still the same inside and provides portable power. Some are larger for pump trucks.

So great to meet Erika Schrader (finally) during World of ConcreteBobcat Team Member

So great to meet Erika Schrader (finally) during World of ConcreteBobcat Team Member

The wheel loader has a quick attachment system, and at World of Concrete, the team had a high-flow sweeper attached. The 74-horsepower machine’s bucket holds 1.2 cubic yards and has high-flow hydraulics. Other specifications are:

- Two-speed gearbox

- Speeds up to 24 miles per hour

- Auto ride control senses the load and cushions the ride

- Air-ride seat

- A Workgroup joystick that rides with the seat

- 5-inch display

- Rear camera ready (not standard)

FleetWatcher

During World of Concrete, FleetWatcher introduced the newest telematics functionality for its construction telematics platform—Small Tools and Attachment Tracking. One customer is currently beta-testing the system. Using the app, users can search for an individual asset, see a group of assets on a specific project or look at all assets in a certain class.

The small tools tracking functionalityFleetWatcher

The small tools tracking functionalityFleetWatcher

This new capability was added because contractors often have a problem tracking expensive equipment that is not a dirt mover. This new functionality allows contractors to keep better tabs on equipment and better visibility on the location of tools and attachments, including which equipment an attachment is on.

This functionality is not a standalone solution. It works in tandem with the FleetWatcher telematics system.

Command Alkon

Joe Johnson, solutions specialist with Command Alkon, discussed Real-Time Ready Mix Concrete Properties with Load Assurance during a presentation at the booth. In addition to many features, the Load Assurance system allows mixer drivers to know the in-transit load properties. The information is gathered by a probe in the mixer drum. Load Assurance combines advanced software and hardware.

The sensor and software help drivers know when loads are fully mixed and the water-cement ratio, among other parameters. This functionality helps attract and retain drivers because it removes the driver's responsibility for the load and drivers get onboarded and ready to work more than 50% on average. It allows drivers to just focus on driving.

Another benefit is reduced lost loads and reliable load specs throughout the delivery process. The system records all water additions and overcomes opinions and assumptions about the mix properties. The savings from the reduced time alone can reach $462,000 on a gain of 10 minutes per load.

The presentation at the Command Alkon boothLori Ditoro

The presentation at the Command Alkon boothLori Ditoro

The system also improves batch efficiency and materials management. It provides:

- Load advice

- Slump measurement

- Data to the plant operator for every load

- Returned concrete alert that shows whether the concrete can be reused

- Overmixing and water addition alerts

The data provides a summary of efficiency opportunities including yard mixing minutes and time spent adding water. Driver coaching based on the data is also a benefit and allows for supportive conversations about non-productive opportunities like trucks waiting or rejected concrete.

Trimble

The Trimble team has a goal of helping smaller contractors adopt technology.Trimble Team Member

The Trimble team has a goal of helping smaller contractors adopt technology.Trimble Team Member

To control grade and slope, concrete pavers have two options: automation/technology or string control. String control can be a safety hazard and can be moved, causing the grade or slope to be incorrect.

At the show, Trimble talked with many smaller contractors who have not yet entered the technology world. They discussed that they need a financial justification. However, the main justification is that the team can save time and money. Smaller concrete contractors could benefit the most from technology. Garcia recommends that contractors not assume that they are too small for technology. A goal for Trimble at World of Concrete was to help smaller contractors find an entry point to adopt technology.

Jack Young, product manager, Trimble, also wants to help contractors find the entry level to begin using technology solutions. However, enterprise contractors typically have different teams for each workflow. Smaller contractors may be unsure about how to invest in technology. The first thing to know is that technology doesn’t cost the same as a piece of equipment.

One suggestion is to bring surface and earthmoving in-house with Trimble Earthworks Go! 2.0. This system is controlled using the end user’s cell phone. The hardware is attached with a magnet, not welded. For example, an automatic grade rod can be installed by the user in under 30 minutes.

Siteworks Machine Guidance allows concrete contractors to enter 3D technology with one investment, providing layout and guidance in one product. The system is a two-for-one deal. The same hardware and software are used for surveying and machine guidance. It includes a machine guidance and survey rod (GPS with tilt compensation). After surveying is completed, the rod can then be mounted on the excavator. The Trimble team doesn’t want smaller contractors to feel left behind.

DEVELON

Taking a seat in the DEVELON DX225LC-7X ExcavatorJonathan Kozlowski

Taking a seat in the DEVELON DX225LC-7X ExcavatorJonathan Kozlowski

The cab has a one-touch power boost for hydraulics and provides operator comfort with a heated, air-suspension seat. A cooling seat is an optional addition. The cab also includes an automotive-style heating and cooling. DEVELON fleet management telematics is standard.

Our team learned about the DX225LC-7X that also help a contract’s bottom line by adding efficiency with its weighing system.DEVELON North America Team Member

Our team learned about the DX225LC-7X that also help a contract’s bottom line by adding efficiency with its weighing system.DEVELON North America Team Member

LED lighting can be found all around the machine for safety and visibility. Speaking of visibility, a rearview camera is standard, and a 360-degree camera is optional. To prevent vandalism, the engine compartment if lockable.

Concrete contractors have been receptive to the electric over hydraulic and the confined space limits of the arm swing, which provides more control. This excavator can also help a contract’s bottom line by adding efficiency with its weighing system. It also doesn’t have a diesel particulate filter, which eliminates this maintenance concern.

B2W Software

The B2W team discussed how the software helps contractors win more bids at better margins and helps them after they win work,B2W Team Member

The B2W team discussed how the software helps contractors win more bids at better margins and helps them after they win work,B2W Team Member

- Operations for critical workflows

- Proactively managing profits by knowing job costing and production in real time.

- Equipment maintenance modules with preventive maintenance and break-fix on all equipment; Helps shops avoid unplanned downtime

All activities come together, connecting the field and office. Both areas have visibility on how to manage operations. The platform is configurable and customizable. In addition, the B2W team helps with implementation and training.

Topcon Positioning Systems

Our team visited the Topcon booth and learned about some small new products that are components of a larger system. The main one was MC Mobile, which has been in the field for about two years. It is a more robust platform.

Thrilled to learn more about the MC

Thrilled to learn more about the MC

Mobile systemTopcon Team Member

We explored the LPS, which has a 3D laser to measure. The MC Mobile tablet takes the place of data collector. If the target (the tablet) moves, the 3D laser follows it. It is used to measure, design and build. Surveying is a manual process that takes lots of time. MC Mobile simplifies the process. End users can also design on the tablet. Afterward, it becomes the control box for the equipment.

While traditional surveying requires a clear view of the sky, the LPS system from Topcon doesn’t need a view of the sky. The system makes machine control affordable and easy to implement for smaller contractors.

MC Mobile started with CTLs but is expanding to larger machines like excavators. The decision to move to excavators next was customer-driven. Operators tend to over-excavate. The Topcon technology prevents over-excavating and adds safety to excavation operations. It is an agnostic for any machine and is an aftermarket solution.

Vanguard Commercial Power

Vanguard featured its new motors and controllersVanguard Team Member

Vanguard featured its new motors and controllersVanguard Team Member

During World of Concrete, Vanguard displayed more battery-powered equipment than the team had at any show before. That included an EDCO saw and a Somero Electric screed.

New at World of Concrete were the motors and controls that expand the Vanguard electrification portfolio. They allow the company to offer a full battery system. The new automotive-grade MVG Series Motors and MC Series Motor Controllers include different power options to meet voltage needs across equipment sizes. The MVG Series includes the MVG1500, MVG2200, MVG3000 and MVG4000 motors. The MC Series includes MC2000, MC4000 and MC8000 motor controllers.

The controllers are available now. The motors will be available later this year.

FARO

FARO shared the Flatness Check app. With an iPad, end users can quickly analyze how flat a surface is. The time required is about 4 minutes.FARO Team Member

FARO shared the Flatness Check app. With an iPad, end users can quickly analyze how flat a surface is. The time required is about 4 minutes.FARO Team Member