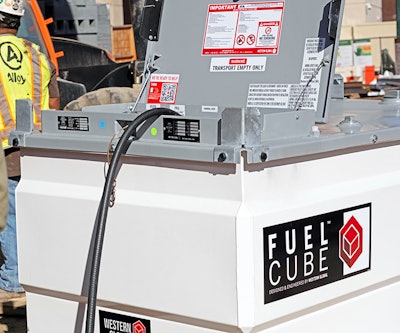

Western Global has announced upgrades to its FuelCube onsite fuel tank. The revamped FuelCube offers several new features, such as four-way forklift pockets, an improved lid, built-in emergency vent and lighter-weight design.

The two smallest sizes can also now be transported around a garage or smaller work environment with a pallet jack when empty. The FuelCube is offered in four sizes to match jobsite capacity requirements and is designed for stationary applications.

Western Global

Western Global

“The FuelCube is one of our most popular fuel storage solutions and is used on a variety of jobsites ranging from general construction to major infrastructure projects,” said Jeff Lowe, vice president of product marketing at Western Global. “While the FuelCube has been a leading product for us, we don’t settle for good enough. The market and our customers are always changing and facing new challenges and opportunities. It’s important to us to remain attentive to customers and ready to offer enhancements that make their jobs easier.”

The FuelCube’s improved lid offers an attached leash. Safety continues to be at the forefront of the new FuelCube’s design. It features a flange with a vent on top of the FuelCube that meets venting requirements without using accessory ports, leaving them open for telematics or other customer accessories.

Western Global

Western Global

The FuelCube now offers four-way forklift pockets that allow it to be moved around the work area with a forklift when empty. The new design uses less metal than the previous model, making the 250- and 500-gallon versions light enough to be relocated with a pallet jack. This also means the new FuelCube uses less trailer weight, allowing it to be hauled at the same time as heavier equipment like generators. Though lighter than before, the revamped FuelCube maintains its durability for tough jobsite applications.

The upgraded FuelCube comes in 250-, 500-, 1,000- and 1,800-gallon sizes. Its 110% double-walled containment eliminates the need for a secondary basin. The FuelCube also offers a removable inner tank for cleaning and inspection. It features corner brackets that allow users to save space on the jobsite by stacking it up to two-high when empty. Additionally, a lockable equipment cabinet increases security for the fuel supply.