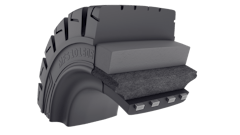

Trelleborg offers the XP1000 tire for rugged and intense applications on construction sites. The XP1000 tire delivers performance, with extra traction and minimal tire vibration during use. This tire is available in a variety of rubber compounds, including ProTEX: a non-marking electrically conducting compound engineered for material handling applications operating in potentially explosive environments.

Equipped with Pit Stop Line technology, Trelleborg XP1000 is shown to support safety and tire change planning. Once 100 hours of operating time remains, an orange band appears on the tread, helping forklift drivers and fleet managers schedule tire changes.

“Our extensive Trelleborg XP range gives operators a wide selection to choose from our complete resilient solid tire portfolio, depending on the material handling application they need. We are proud to be a strategic partner to the forklift industry, delivering advanced solutions to support our customers maximizing their performance under any working conditions while minimizing the environmental impact. We have worked hard to make sure our tires are ready for next generation of material handling vehicles and the intense jobs they’re required to perform," said Anton Stoynev, director material handling and construction, Trelleborg Central Europe.

![[VIDEO] Trelleborg Introduces Construction Pneumatic Tire Line](https://img.forconstructionpros.com/files/base/acbm/fcp/image/2017/03/default.58c01981e43c9.png?auto=format%2Ccompress&fit=crop&h=75&q=70&w=75)