Toyota Material Handling (TMH) continues to raise the bar in forklift automation. This month, the forklift brand unveiled two new automated guided vehicles (AGVs) that add the latest in proven automation technology to existing trusted Toyota products.

Toyota Material Handling’s new Center-Controlled Rider Automated Forklift and Core Tow Tractor Automated Forklift will transform how customers meet their manufacturing, warehousing, and distribution challenges.

“When customers choose to work with Toyota, they gain more than just an automation partner. They get a full-line material handling solutions provider capable of meeting all their material handling challenges,” said Bill Finerty, TMH senior vice president of sales. “We’re here to help our customers through their entire optimization journey.”

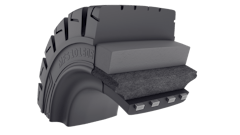

The Center-Controlled Rider Automated and Core Tow Tractor Automated Forklift can each be manually operated when needed but are also powered by Light Detection and Ranging (LIDAR) natural features navigation. Both products require little or no additional infrastructure or setup and can be integrated into customers’ existing operations safely, seamlessly and efficiently.

With towing capacities of up to 10,000 pounds for the Core Tow Tractor Automated Forklift and lifting capacities up to 7,000 pounds for the Center-Controlled Rider Automated Forklift, these products are designed to position and maneuver with accuracy, offering accuracy tolerance ranges as narrow as a half-inch.

Toyota automated forklifts accomplish this by utilizing advanced sensors that also prompt the vehicle to slow or stop when an unmapped object is detected in its path. They are engineered to detect mapped structures behind objects, meaning an errant pallet or object will not interrupt normal operation.