Toyota Material Handling has launched a new line of electric pneumatic forklifts with its 48V and 80V models. This durable line is built to withstand outdoor terrain and work in various weather conditions. The forklifts are designed for retail applications such as lumberyards, home centers, landscaping and store support.

“Our goal at Toyota is to embrace the spirit of Kaizen – or continuous improvement – in everything we do and every product we offer,” said Tony Miller, Toyota Material Handling senior vice president of engineering, operations and strategic planning. “These new 48V and 80V electric pneumatic forklifts set a new standard in quality material handling solutions, helping elevate work efficiency for operators with the integration of cutting-edge technologies and versatility across a wide range of tasks and terrains.”

These new models feature six different lift capacities ranging from 3,000 to 7,000 lbs. Toyota’s innovative System of Active Stability (SAS) springs into action when operators encounter unanticipated loads and speed conditions. Additionally, Toyota’s Operator Presence Sensing System (OPSS) along with the optional Seatbelt Interlock encourages operators to maintain a properly seated position with the seatbelt buckled or travel and load handling operations will be limited.

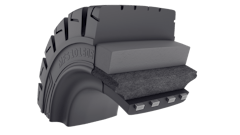

Built with standard AC drive and lift motors, along with low noise and vibration levels, this forklift provides reliable operation. The regenerative braking system adjusts the speed of the truck when the operator’s foot is removed from the accelerator and conserves energy when speeds begin to slow by returning energy to the battery. An optional Slope Assist feature maintains the speed of the forklift on a slope by switching the power mode of the truck.

The load-sensing power steering capabilities facilitate handling for operators, while also keeping power in the battery.