Quoted in a New York Times article, "It’s going to be a heavy precipitation event," says Bob Oravec, a forecaster with the Weather Prediction Center.

It was. It ended up being a bit of an understatement, but nevertheless accurate. This story is about the repair of a bridge, so it's fairly clear where this will be going. But we are not talking about one rainy event.

There was 12.

In March 2023 regions California experienced “12 consecutive atmospheric rivers that really soaked and saturated the soil,” says California Department of Transportation (Caltrans) District Five. This put - amongst everything else - the Limekiln Creek Bridge at risk. After inspection, engineers discovered a serious situation within the crib wall.

EagleLIFT

EagleLIFT

Atmospheric rivers can be described as "rivers in the sky." The National Oceanic and Atmospheric Administration explains that these are long, narrow regions in the atmosphere that carry water vapor outside of the tropics. They say that normally they are capable of carrying "the equivalent to the average flow of water at the mouth of the Mississippi River" (roughly 593,000 cubic feet per second, while strong atmospheric rivers can transport up to 15 times that).

Meteorologists advised people to prepare emergency kits and postpone travel as much as possible as flooding and threats of avalanches.  EagleLIFT

EagleLIFT

The iconic Highway 1 hugs the central California coastline and Santa Lucia Mountains through its scenic Big Sur section. The bridges that span the many creeks and canyons are engineering marvels like the Rocky Creek, the Big Creek, the Bixby Creek Bridge (one of the tallest single-span concrete bridges in the world spanning 714 ft.) as well as the Limekiln Creek Bridge.

Besides scenic coastal beauty, the stretch of highway is also famous for flooding, erosion, and rock and mudslides. Due to the record rain and storms, sections of Highway 1 have been closed for months.

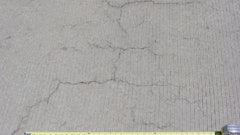

The Limekiln Creek Bridge sits over Monteray County’s Limekiln Creek. It's a 6-span prestressed precast I girder bridge built in 1957 and has been tapped for replacement as part of a complete realignment of the highway for almost a decade. When maintenance staff noticed gaps in the crib wall (a permeable gravity retaining wall) supporting the slope around the bridge’s northern abutment—which in turn supports the highway—they immediately called the engineers at Caltrans. Caltrans’ District Five then called EagleLIFT Inc., a general engineering contracting company which specializes in lifting, leveling, and soil stabilization solutions for California and Nevada.

EagleLIFT was founded in 1995 by Donald J. Moody, a retired Air Force colonel. The majority of their work utilizes an expanding foam to lift pavements or roadways, though provide a void filling service. Recently, in the last two to three years, due to rising ocean levels and increased tidal action, there has been more problems with wash out behind sea walls.

A void behind a seawall can cause a loss of stability and sinkholes. Stormwater and tidal at Limekiln Creek Bridge had washed out all the fines in the aggregate and cobbles placed between boulders within the crib walls. This washout caused concern on the stability of the hillside as the only thing that was holding it back was the crib wall. Concerns were that if conditions were to continue to deteriorate (and many were assuming they would if nothing was done), the crib wall would fail potentially leading to a landslide.

Despite having a backlog of work, EagleLIFT recognized the situation as an emergency repair and immediately responded. They were out there within the week.

EagleLIFT

EagleLIFT

EagleLIFT

EagleLIFT

Normally, reconstruction of a hillside would require the entire roadway shutdown for weeks. While work was originally estimated to be five to six days - EagleLIFT was able to get the job done with very little disruption. They hired a qualified traffic control subcontractor with flaggers, they had to only close one lane, 50% under budget and completed in about two days working normal day hours.

Access to the site was a special challenge. The steep 45 to 50-degree bank required the EagleLIFT team to scale down the hillside to find access to the crib wall. The truck and pump were parked at the top with hoses hung overside some 200-ft. below.

EagleLIFT contractors examining a void in the bridge crib wall. After all fine and aggregate was washed away, only about a 2-in. thick layer of concrete roof held the bridge up. Here, the void was estimated to be roughly 8 ft. tall.EagleLIFT

EagleLIFT contractors examining a void in the bridge crib wall. After all fine and aggregate was washed away, only about a 2-in. thick layer of concrete roof held the bridge up. Here, the void was estimated to be roughly 8 ft. tall.EagleLIFT

EagleLIFT

EagleLIFT

EagleLIFT pumped around 5,000 lbs. of Strata-Fill 24-023 through the steel rods into the voids. "It follows the path of least resistance and finds voids we didn’t even know were there. One void behind that wall was large enough to stand up inside,” says Frazao. He also says the product has other benefits, “It’s lightweight, so it doesn’t add extra pressure on the soil, and has a low exothermic reaction temperature, which means it generates very low heat during the polymerization reaction. That’s an ideal characteristic for closed spaces like these voids where you don’t want overheating or a smoldering fire.”

NCFI manufactures polyurethane foam systems for spray foam insulation (SPF), geotechnical, agricultural, SPF roofing, marine flotation, aerospace, molding, and many other uses. The company offers a complete line of flexible foams for furniture, transportation, bedding, carpet underlay, and packaging.

EagleLIFT

EagleLIFT

Lifting and void-filling work is specialized and (aside from having the right equipment) it comes down to choosing the right product for the situation. "There's different types of polymers depending on what you're doing," says Frazao. After doing this for 25 years, he's learned enough to start asking the right questions to assess and determine the next steps: "What are we trying to do? Are we filling voids? Are we lifting? What are we lifting (roadway, a house or building)?" The type of soil and the type of load all play a role in choosing the correct product.

"One foam does not do everything. Some people think that and learn the hard way," he says. "That's where the experience comes into play - knowing which polymer will serve the customer the best and give the result that they're looking for."

Strata-Fill is a two-part structural polymer made specifically to fill large voids, not lifting. Typical roadway lifting foams use a chemical reaction causing high heat for the expansion. Void fillers, like Strata-Fill's low exothermal reaction doesn't. With the amount used, Frazao explains that the polymer could insulate itself enough to cause it to burn itself from the center out.

"Compared to alternative methods of fill, like lightweight concrete, cellular concrete, or even straight concrete, the use of polyurethanes reduces that load bearing weight on questionable soils," says Patrick Burchett, NCFI Polyurethanes Technical Manager.

The product itself was created for the pipeline industry. Roughly 15 years ago, explains Burchett, it was originally used as erosion control for trench breakers instead of sandbags. He kept searching for different products to use in various types of geotechnical applications like concrete lifting and evolved from there. They have other products in the same weight range as well as a hydrophobic system that will react in the water for void filling or annular grouting or pipe abandonment.

While the compressive strength wasn't a spec requirement for the repair job, Strata-Fill provides a 44-psi compressive strength or about 8,000 lbs. per square foot. Once cured, Frazao says it can be almost as hard as concrete. While there is a structural strength, it isn't enough expansion pressure to cause unintended damage.

Another aspect that made Strata-Fill a candidate for the void filling was its environmental considerations. Due to the close proximity to the ocean, any product used needed to have passed all environmental tests to not contaminate water or soil. NCFI is going through NSF-61 testing (NSF-61 is a standard concerned with water safety). Their products originally had approval, but some formula changes required recertification to verify no leaching of the system.

Frazao likens this type of project to repairing your car, comparing the low cost of some work early to replacing the entire engine. "Replacing that crib wall would cost millions and take many months. Kudos to the maintenance staff for contacting Caltrans, and to Caltrans for doing proactive, preventive maintenance by calling EagleLIFT. If the check engine light comes on in your car, you can either say ‘I’ll worry about that later’ or drive to the mechanic and get it fixed. That choice can mean the difference in a small repair bill and the cost of a new car."

Frazao says the repair is more just a quick temporary fix, “It will last until the finally get around to building a new bridge over Limekiln Creek.” While Strata-Fill has been tested to last longer, it's been rated with a 50-year lifespan.