AGM vs. Lithium highlights:

- AGM is a relatively new technology compared to traditional lead-acid. AGM batteries no longer require daily maintenance like adding distilled water; however, they have many other disadvantages of lead-acid technology: limited capacity, inconvenient charging, voltage drop with battery discharge, energy losses due to battery heating, cooling requirements, and so on.

- These disadvantages typically do not allow a single-battery operation with an AGM technology. Two to three AGM batteries are required per forklift to be swapped between shifts.

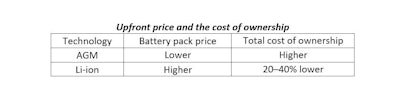

- The total cost of ownership of a forklift fleet powered by AGM batteries is 20-40% higher than lithium-ion batteries.

- TPPL is a type of AGM that has one distinct advantage: a high charge absorption rate at the initial stage of charging; yet TPPL retains the key disadvantages of lead-acid batteries.

What is an AGM Battery?

What does AGM battery mean? Absorbed Glass Mat (AGM) is a modern variant of a lead-acid battery. This battery should not be confused with a gel battery because there are significant differences between these types. A gel battery is engineered using a gel paste that suspends the electrolyte inside the battery case. In an AGM battery, the electrolyte is stored in a glass mat and can never spill. AGM has a big safety advantage in a head-to-head comparison of AGM vs a standard battery.

For a hundred years lead-acid battery chemistry remained unchanged. The first significant technology improvement came with the introduction of the “pasting process” instead of flat plates in the construction of electrodes. These electrodes consist of a lead-alloy grid filled with a porous lead paste and can now provide more energy than foils or flat electrodes.

The second major modification was the use of AGM separators instead of conventional separators. This invention resulted in a sealed lead-acid battery, or SLA battery. In an SLA battery, including the AGM type battery, gas recombination occurs, and electrolyte concentration remains constant. Today, an AGM deep cycle battery is widely used in pallet trucks, forklifts, and so on.

Another important modification was the use of pure lead instead of lead, calcium, and tin alloy in plates of decreased thickness, giving the technology the name “thin plate pure lead,” or TPPL. This new technology can absorb more charge than the standard AGM battery, and at a faster rate. However, this is only true for the initial stages of the charging process; the charging rate decreases sharply as the battery reaches a state of charge (SoC) of 70–80%. Charging time remains considerably higher than any lithium battery (for more information, see Lithium vs. TPPL Battery Overview).

What is a Lithium-ion Deep Cycle Battery?

Most modern off-highway industrial vehicles, such as forklifts, can benefit from using lithium-based batteries. A power pack capacity may be in the range of 100 to 1000 Ah, though the capacity can be further increased by adding cells in series or parallel.

Material handling equipment has specific requirements based on the particulars of operations:

- Equipment utilization is high, with up to 18 work hours per day with short breaks.

- Chargers are located nearby.

- Unlike with an EV, battery weight is often welcome as a counterweight in bigger trucks.

You can learn more about the design of lithium cells used in forklift batteries here: What’s Inside the Black Box? The Form, Design, and Chemistry of Lithium Forklift Battery Cells.

Comparison of Key Technology Indicators

OneCharge

OneCharge

Both AGM and TPPL provide lower ROI within 2–4 years when used in forklift operations with moderate to high energy throughput. Lithium batteries normally save 20–40% of the total cost of ownership when users switch from lead-acid batteries:

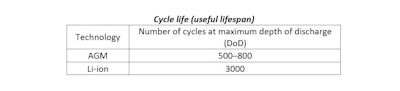

- Lithium batteries last longer with 3-4X the cycle life of a lead-acid battery.

- Lower infrastructure costs (lighter and smaller chargers, no need for the additional battery room, ventilation, and extra HVAC for battery cooling).

- Lower energy use (around 30% of the electricity used to charge an AGM battery is lost on heating).

OneCharge

OneCharge

All other conditions being equal, the 4–6x higher number of cycles makes a lithium battery a far more valuable and sustainable power source than any lead-acid battery, including AGM and TPPL versions. Having a few lead-acid batteries per truck generates far more waste than a single-battery operation with a lithium battery, which may outlive the host forklift and be repurposed for other applications, like grid energy storage.

OneCharge

OneCharge

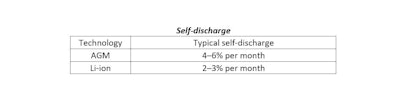

Self-discharge indicates how quickly an unused battery is discharged when not in use. In some applications, a battery may sit idle in the “off-season” or between planned operations. Therefore, one great benefit of a lithium battery is that it lets a user charge a battery one day before its planned use, providing a full, ready battery, without having to do regular maintenance to keep it in working order.

OneCharge

OneCharge

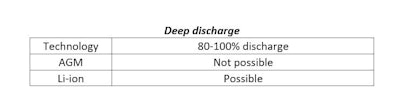

If a lead-acid battery cell is deeply discharged it may get damaged and become incapable of recharging again. By contrast, even though it is recommended to discharge a lithium cell to 40–50% SoC to prolong its cycle life, a lithium cell can be discharged to zero with no loss of capacity, and no other damage to the cell.

OneCharge

OneCharge

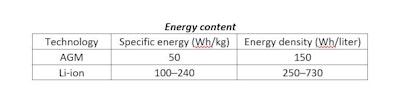

High specific energy is critical for passenger EVs, when the distance that a car can cover without charging depends on its main battery, and a charger may not be available nearby. That is why light lithium batteries with high energy density became the main power source in modern EVs.

This parameter is less important for any electric forklift battery when power at the facility is always available for charging.

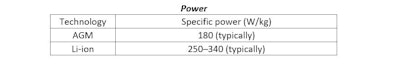

Higher power is required for lifting heavy loads. Powerful lithium-ion batteries improve the efficiency and safety of operations. A powerful battery also prevents unnecessary wear and tear of forklift parts.

OneCharge

OneCharge

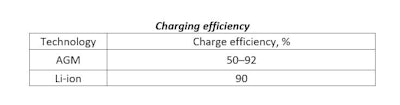

Batteries do not deliver the same amount of energy that was used to charge them; a lead-acid battery is heated during the charging process. In the case of the same energy outcome of AGM and Li-ion, AGM battery charging requires about 30% more energy.

A charging rate of 0.5–1.0 C (100% of a battery capacity in one hour, hence the “C”) is a norm for LFP lithium battery cells. NMC and NCA cells can be charged even faster, up to 2–3C, but this high charging rate is rarely required in material handling with the opportunity charging approach. Besides, the dual charging port of an LFP battery pack allows charging in half the time. Learn more about Li-Ion batteries charging here: 1C Charging Rate Of Li-ion Batteries: A Need or a Fad.

AGM vs. Lithium Battery

OneCharge

OneCharge