Depending on the structural design requirements of a building, the grade of concrete may vary. Concrete pounds per square inch (PSI) plays a significant role in determining the concrete grades that contractors can use for different projects and settings. Soft concrete, for example, is used in most homes, while contractors will often use harder alternatives in industrial settings where the load bearing requirements are much greater.

Concrete PSI can vary from around 2,500 to 6,000 PSI based on the materials within a concrete mixture. Harder concrete is often made up of granite, chert and quartzite while softer concrete is made up of sandstone, shale and limestone.

Concrete Hardness & Floor Removal

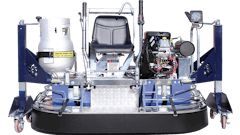

When removing flooring, concrete hardness often determines what tooling can be used. Heavy-duty machines like ride-on scrapers are better suited for areas with harder concrete, while walk-behind machines are suitable for softer concrete. The degree of pressure can also impact the level of damage left behind by a machine. Softer concrete requires a light handling to avoid chunks being removed underneath the machine and dips appearing in its surface.

If dips and rivets are created, contractors can repair the surface using patches to even out the floor before new materials are added on top.

If dips and rivets are created, contractors can repair the surface using patches to even out the floor before new materials are added on top. However, patches are much softer than regular concrete, which makes it easy for contractors to miss them and accidentally pull them up during future removals.

Soft concrete floors are high maintenance compared to harder concrete. For starters, they are far more expensive to grind and polish as their weak surfaces can break down easily. Compared with harder concrete floors, they also need far more hardener to provide strength and durability. Softer concrete may also wear down diamond tooling much faster as softer concrete does not have enough abrasion resistance.

Testing for Concrete Hardness

Before working on a floor, contractors can visit the site and remove a small portion of flooring to assess its condition. Geographic location often dictates the type of concrete hardness contractors can expect to find but this isn’t absolute, so there are tools to help.

Tools that contractors can use to test concrete include the rebound hammer and Moh’s Scratch Test. The rebound hammer features a spring-loaded piston, which is fired by the user onto the surface of the concrete. The amount of rebound provides a PSI rating for the slab.

On the other hand, The Mohs Test rates concrete from one to ten (one being the weakest, ten being the strongest). The Mohs Test kit contains four stylus tools with pointed tips at each end made of materials with varying degrees of hardness, like plastic and copper. Contractors can make a small scratch of the concrete’s surface starting at the highest range and work their way down until the stylus no longer leaves a mark. Then, they can look at the chart provided in the kit to see how the rating corresponds to a particular PSI.

Best Practice

Floor removal on different concrete grades can vary. If contractors are working with softer concrete and residential flooring such and carpet or vinyl, the flooring must be cut into strips before they use a walk-behind scraper to avoid unnecessary damage and added time. Despite all floor removal machines being heavy duty, some can be used for lighter work if necessary. It’s important to let the machine do the work, which means reducing contractor workload and not increasing pressure on the floor.

Harder concrete needs a heavy hand and often a ride-on machine is ideal for the removal of hard goods. Blade and angle choice can also affect how easily a floor can be removed. If the blade is digging into the floor because the pitch is incorrect, the blade will wear more quickly, and it will take longer to remove. It’s also possible for the machine to skip over flooring completely without removing it if there’s insufficient pressure. Meanwhile, too much pressure can cause the blade to snap, damaging the machine.

Concrete grades have a big impact in the methods of floor removal. Understanding the requirements of the different grades allows contractors to effectively remove flooring and prepare the surface for new materials to be laid on top without causing damage.