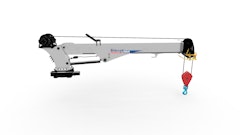

Manitowoc has unveiled the latest addition in its Potain MDT City crane range, the 6 t capacity MDT 159, which fills the gap between the MDT 139 and MDT 189. With a 60 m maximum jib, the crane is designed for small to midsized building projects of up to 10 floors and tight urban jobsites.

The topless concept is ideal for multi-crane work sites as it reduces the clearance needed for other cranes passing overhead or underneath. Just three containers are needed to transport the crane’s full upper section. This reduces the complexity of getting the crane on and off the jobsite, while also minimizing disruption to traffic and the surrounding area.

Assembly is aided by Manitowoc’s Crane Control System (CCS), which improves communication between the crane and on-site staff. The technology also enables the lifting and distribution ropes to be fixed at ground level, reducing assembly work required in the air. Once the crane is ready to work, CCS maintains high standards through performance, ergonomic control and integrated maintenance.

The MDT 159 features two new trolley systems, one with permanent four falls and one with an automatic reeving system, allowing owners to select the best option for them. The DMP trolley is a system that requires only limited maintenance. The permanent double reeving means no adjustment to the ropes is needed on site and the crane’s maximum capacity of 6 t is permanently available. The DMP trolley also offers 0.5 m greater height under hook compared to the SM/DM Quick Lock alternative.

The SM/DM Quick Lock trolley can automatically change reeving at the flick of a switch. This process is managed and secured by the CCS and requires no manual intervention or accessories. This allows owners to take on a wide variety of lifting tasks as required.

The Potain MDT 159 is one of the first models to come equipped with the new Potain CONNECT telematics system. This remote technology platform supports uptime for cranes through identification and resolution of issues, preventing escalation through earlier insight. It offers remote access to crane data for troubleshooting and fleet management, enabling Potain customers to get more from their machines.

“When developing new cranes, we are fully focused on our customers’ needs – helping them to get the job done quicker and easier. Tight, congested jobsites are becoming increasingly common, making transport optimization and straightforward assembly more important than ever. We have listened, and designed the Potain MDT 159 as the perfect city crane,” said Thibaut Le Besnerais, vice president for brand and product management, tower cranes, at Manitowoc.

Like other Potain MDT City cranes, all mechanisms on the MDT 159 are driven by frequency inverters. Lifting power comes from a 33LVF15 hoist winch.