Out-of-position anchor bolts occur when the measured deviation or variation from the specified location or alignment exceeds the specified construction tolerance. To avoid schedule delays and costs associated with out-of-position anchor bolts, you must understand what tolerances your work will be judged by and take the necessary actions to position, align and secure the anchor bolts.

Industry-Standard Tolerances

The concrete and steel industries both provide anchor bolt tolerances. Unfortunately, the tolerances are not compatible. Tolerances provided by the American Institute of Steel Construction (AISC) are more restrictive than anchor bolt tolerances provided by the American Concrete Institute (ACI).

For the steel erector, Division 5 of the specifications references AISC 303 “Code of Standard Practice for Steel Buildings and Bridges” while Division 3 of the specifications for the concrete contractor typically references ACI 117 “Specifications for Tolerances for Concrete Construction and Materials”.(1,2) Even though the architect/engineer should clarify and resolve these tolerance differences, concrete contractors sometimes become involved in construction disputes because of the non-compatible tolerances.

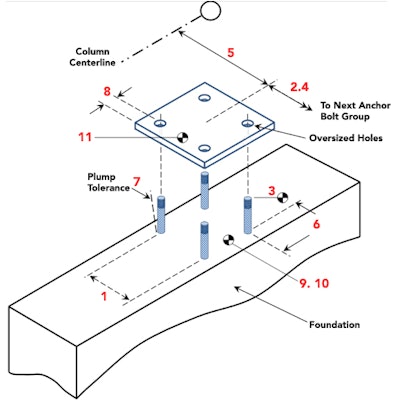

Figure 1: Anchor bolt and base plate tolerances. (Modified from reference 5)

Figure 1: Anchor bolt and base plate tolerances. (Modified from reference 5)

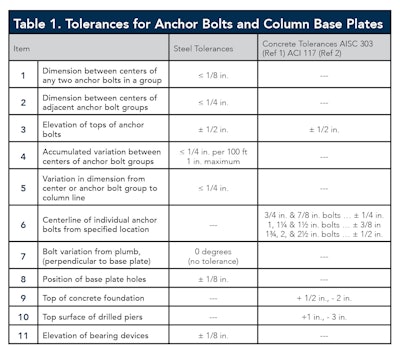

As shown in Table 1 (below) and Figure 1 (above), AISC tolerances place limits on the variation between centers of any two bolts in a group (Item 1), centerlines of bolt groups (Items 2 & 4), and centers of anchor bolt group from column lines (Item 5). ACI 117 only specifies elevation (Item 3) and a location tolerance for the centerline of individual anchor bolts (Item 6). As shown for (Item 7), AISC has a very strict or zero plump tolerance for bolts whereas ACI does not specify a plumb tolerance. The only compatible tolerance between AISC and ACI is the top elevation of the bolts (Item 3). AISC’s tolerances combined with oversize holes in the base plates ensure the steel structure can be easily erected without modifying the structure.

Table 1: Tolerances for Anchor Bolts and Column Base Plates.

Table 1: Tolerances for Anchor Bolts and Column Base Plates.

For anchor bolts to satisfy both AISC and ACI’s tolerances, Suprenant and Malisch claim anchor bolts must be located within ± 1/16 inch of their specified location.(3) A tolerance of ± 1/16 inch is neither realistic nor achievable. Therefore, it is critical for concrete contractors to understand what tolerance applies to the concrete work – AISC or ACI tolerances? AISC recommends that Division 3 of the specifications require anchor bolts to be set in accordance with the AISC 303 “Code of Standard Practice”.(4) Even using plywood or steel templates to position, align and secure anchor bolts, it is highly unlikely the concrete contractor can satisfy the AISC tolerances shown in Table 1. AISC’s tolerances are too restrictive for standard anchor-bolt placement techniques.

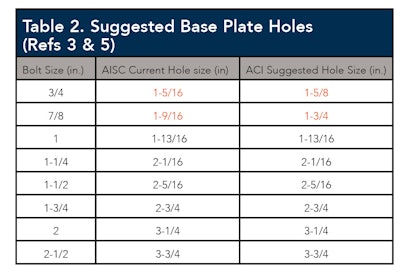

Using AISC’s recommended oversize base plate holes and ACI’s anchor bolt tolerances should allow for easy erection of the steel structure without modifying the structure for 1, 1-1/4, 1-1/2, 1-3/4, 2 and 2-1/2 inches diameter bolts. However, that may not be the case for 3/4 and 7/8 inch diameter bolts.(3) As shown in Table 2 (below), AISC’s recommended oversize-hole diameters for 3/4 and 7/8 inch bolts are too small as compared to oversize hole sizes suggested by ACI.(3,5)

Table 2: Suggested Base Plate Holes.

Table 2: Suggested Base Plate Holes.

Concrete contractors seldom control the size of the base plate holes. So, don’t rely on oversize holes to mitigate out-of-position anchor bolts. Always take care when positioning, aligning and securing anchor bolts regardless of the bolt size but extra care may be required for 3/4 and 7/8 inch diameter bolts.

Where & How to Measure

Adding to the complexity of anchor bolt tolerances is the difficulty in accurately measuring the location of individual and groups of anchor bolts. It is standard practice to layout the location of anchor bolts along the top of the concrete. However, anchor bolts locations are commonly verified by measuring to the top of the bolt. If the anchor bolt is not perfectly plumb, the location of the top of the bolt will not be the same as along the concrete. For a bolt tilt of 5 degrees and a 6 inch bolt projection, the difference between bolt location as measured from the top of the bolt and top of the concrete can be as much as 1/2 inch.(3)

As shown in Table 1, tolerances are measured from centers of anchor bolts (individual or groups) and centerlines of bolts. Using these measuring points require estimating the centers which introduce more measuring errors and uncertainties. Also, the accuracy of the anchor bolt location depends on the accuracy of the measuring tape and the layout or reference lines. Too improve layout accuracy, make a plan on where and how to measure and double check your layouts.

Dennis Purinton with Purinton Builders, Inc. (East Granby, Conn.) makes plywood anchor bolt templates in the shop as shown. Purinton says it is just important to mark the template alignment relative to the foundation as measuring and drilling the bolt holes in the correct location.

Dennis Purinton with Purinton Builders, Inc. (East Granby, Conn.) makes plywood anchor bolt templates in the shop as shown. Purinton says it is just important to mark the template alignment relative to the foundation as measuring and drilling the bolt holes in the correct location.

All methods for relocating, realignment anchor bolts or base plate modifications require the approval of the architect/engineer. The Code of Federal Regulations, 29-CFR Chapter XVII, Section 1926.755 (B) for column erection stability, states:

a) Anchor rods (anchor bolts) shall not be repaired, replaced, or field modified without the approval of the project structural engineer of record.

b) Prior to the erection of a column, the controlling contractor shall provide written notification to the steel erector if there has been any repair, replacement or modification of the anchor rods (anchor bolts) of that column.

In closing, be sure to understand what anchor bolt tolerances apply to your job, use either single or double templates with double nuts to position, align and secure the anchor bolts. Before placing concrete, recheck the anchor bolts for proper location and alignment.

References

- AISC 302-10 Code of Standard Practice for Steel Buildings, American Institute of Steel Construction (AISC), April 14, 2010, www.aisc.org

- ACI 117-10 (Reapproved 2015) Specifications of Tolerances for Concrete Construction and Materials and Commentary, American Concrete Institute (ACI), 2015, www.concrete.org

- Suprenant, B. A., and Malisch, W. R., Tolerances for Cast-in-Place Concrete Buildings, American Society of Concrete Contractors (ASCC), 2008, www.ascconline.org

- Fisher, J. M. and Kloiber, L. A., Steel Design Guide 1, Base Plate and Anchor Rod Design, 2nd Edition, American Institute of Steel Construction (AISC), 2006, www.aisc.org

- ACI 117.1R-14 Guide for Tolerance Compatibility in Concrete Construction, American Concrete Institute (ACI), 2014, www.concrete.org

- Putkey, J. J., Steel Tips – Common Steel Erection Problems and Suggested Solutions, Structural Steel Educational Council, December 1993, www.steeltips.org