From trailer-mounted boom lifts to the highest-reaching “super booms,” before work can begin, equipment needs to be transported from the rental yard to the jobsite. To do this safely and efficiently, there are some important considerations. And, while models and equipment types will vary in their requirements and procedures, a couple important safety rules apply across all machines.

The first rule is to read the operator’s manual. The operator’s manual provides step-by-step instructions to ensure the boom is being loaded safely and efficiently. And second, when loading and unloading equipment, the transport vehicle should be parked on a firm surface and secured in order to prevent it from rolling.

Now, with those first two steps done, it’s time to prepare your equipment for transport.

When you’re talking about a large piece of aerial equipment such as a boom lift, you need to make sure that platforms, jibs, booms, and axles are fully lowered and/or retracted and in transport position. Again, the operator’s manual is an important resource, as it should describe the correct “transport position” for the specific model you’re loading. Whenever possible, the boom should be transported with the platform floor horizontal to the transport trailer bed. Select booms and trailer combinations do not accommodate this orientation due to length, in which case, it’s critical to follow the manual for proper positioning and securing the platform.

Additionally, watch out for hazards during loading. This includes anything that might be a tip-over hazard, a collision hazard resulting from limited sight distance, and/or blind spots, as well as overhead hazards such as power lines. Only qualified aerial lift operators should move the machine on or off the transport truck. Once the boom is loaded, look over the entire machine for any loose or unsecured items. Always use a turntable rotation lock pin, checking to make sure the key switch is in the “off” position, and then remove the key before beginning transport.

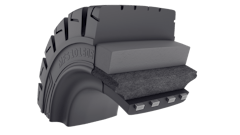

Now it’s time to secure the platform. Appropriate restraints based on weight and local regulations should be placed parallel to the machine’s restraint guides, taking care that you don’t use too much downward force to secure them. Put some sort of force-absorbing material, such as foam, rubber, or wood, opposite the restraints to reduce any movement during transport. The chassis of the boom also must be secured to the transportation platform using a minimum of six chains. Make sure the chains have ample load capacity and adjust the rigging to prevent any damage to the chains or the lift. For a diagram, refer to the "Lifting Instructions" in the operator’s manual.

For some jobsites, trailer-mounted boom lifts, such as the Genie TZ-34 and TZ-50, can offer the up, over, and out reach needed for the job, along with the benefits of ease of transport and mobility. Because they can be towed behind a pickup or SUV, trailer-mounted boom lifts can be a productive and practical option for the right jobsite.

Again, it’s important to read the operator’s manual and ensure that the transport vehicle is parked on a firm surface and secured before attaching a trailer-mounted boom lift to the vehicle that will tow it.

Additionally, when attaching a trailer-mounted boom to any vehicle, it’s important to check that vehicle’s towing capacity, even if it has towed similar equipment before. That’s because the weight of a TZ can fluctuate based on its options. Once the necessary towing capacity is confirmed, safety chains and brake cables need to be attached to the vehicle. Note that the chains should cross under the hitch.

And finally, when loading or unloading any equipment from a transport vehicle on a public road, extra measures need to be taken. This includes the use of warning cones, hazard tape, signs, and flag personnel. These options can help you safely load and unload the transport trailer and prevent harm to worksite personnel as well as drivers on the road.